About Dealers of hiwin linear in gurgaon

HIWIN linear bearings are precision-engineered components used in linear motion systems. Heres a description:

-

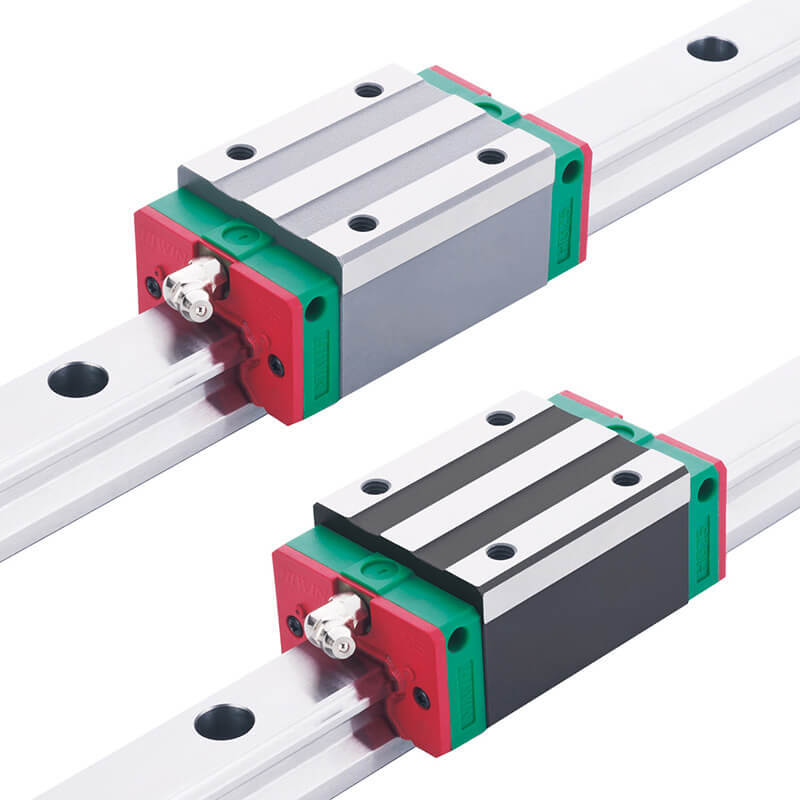

Construction: HIWIN linear bearings typically consist of an outer shell, raceway, rolling elements (balls or rollers), and an inner carriage or block. The carriage or block moves along the raceway, providing smooth linear motion.

-

Material: Constructed from high-quality materials such as hardened steel or stainless steel, ensuring durability and resistance to wear.

-

Design Types: HIWIN offers various types of linear bearings, including:

- Ball Type: Utilizes balls between the raceway and carriage for low-friction, high-precision movement.

- Roller Type: Uses cylindrical rollers for applications requiring higher load capacity and rigidity.

-

Load Capacity: Designed to support both radial and axial loads, depending on the specific model and configuration.

-

Precision: Manufactured with tight tolerances to ensure smooth and accurate motion, suitable for applications requiring high precision.

-

Sealing: Some models feature seals or wipers to protect against contaminants, extending the bearings service life and maintaining performance in challenging environments.

-

Mounting Options: HIWIN linear bearings offer various mounting configurations, including flange mounting, side mounting, and base mounting, providing flexibility for different applications.

-

Application: Widely used in automation, CNC machinery, robotics, semiconductor manufacturing, medical equipment, and other industries requiring precise linear motion.

HIWIN linear bearings are known for their reliability, precision, and smooth operation, making them a preferred choice in various industrial and technology

Versatile Application RangeHiwin linear rails in Gurgaon are used across CNC machining, automation, packaging systems, and robotics industries. Their single rail and block design, coupled with multiple block types, supports both compact and heavy-duty requirements, granting manufacturers and engineers flexibility in motion system design.

Exceptional Precision and Load CapacityDelivering high precision (C5, C7, C10) and robust load support, these rails accommodate dynamic loads up to 47 kN and static loads up to 70 kN. Their four-row structure and reinforced resin cage maximize stability and longevity, ensuring consistent accuracy even in extended operations.

Advanced Anti-Corrosion FeaturesHiwin rails feature a specialized anti-rust coating on stainless steel, complemented by double-sealed blocks and integrated steel retainers. These attributes safeguard guide rails against harsh environmental factors and reduce maintenance intervals, extending the operational life of your equipment.

FAQs of Dealers of hiwin linear in gurgaon:

Q: How can I select the appropriate Hiwin linear guide for my specific application in Gurgaon?

A: Selection depends on factors like required rail length, operating environment, load capacity, and precision needs. Assess your applications conditions and consult with a dealer or supplier for tailored recommendations, considering options such as mounting type, block style, and preload class.

Q: What is the installation process for these Hiwin linear rails?

A: Installation includes choosing between top or bottom mounting, precise alignment of the guide rail, and securing with recommended fasteners. Its essential to adhere to the manufacturers instructions for proper assembly to achieve optimal performance and longevity.

Q: When should I use anti-rust coated linear rails for industrial equipment?

A: Anti-rust coated rails are ideal for environments where exposure to moisture, chemicals, or temperature fluctuations may occur. They provide enhanced corrosion resistance, making them suitable for food processing, packaging, and outdoor installations in Gurgaon.

Q: Where are Hiwin linear rails typically used in industrial setups?

A: Hiwin linear guides are commonly installed in CNC machines, automation lines, packaging equipment, and industrial robots. Their design accommodates high-precision and high-load applications, making them versatile in manufacturing and engineering environments.

Q: What benefits do double-sealed blocks and four-row rail structures offer?

A: Double-sealed blocks prevent ingress of contaminants, while four-row rail construction distributes load more evenly, increasing rigidity and lifespan. These features make Hiwin rails ideal for applications demanding consistent accuracy and durability.

Q: How do I ensure proper usage and maintenance of Hiwin linear rails?

A: Regular cleaning, scheduled lubrication, and inspection of seals extend the lifespan of Hiwin linear rails. Following the manufacturers maintenance guidelines and replacing worn components promptly ensures reliable operation and reduces downtime.

Q: What is the maximum speed and precision rating of these linear rails?

A: Hiwin linear guides can operate at speeds up to 80 m/min with high precision ratings (C5, C7, C10), making them suitable for intricate and fast-moving automation tasks in industrial settings.