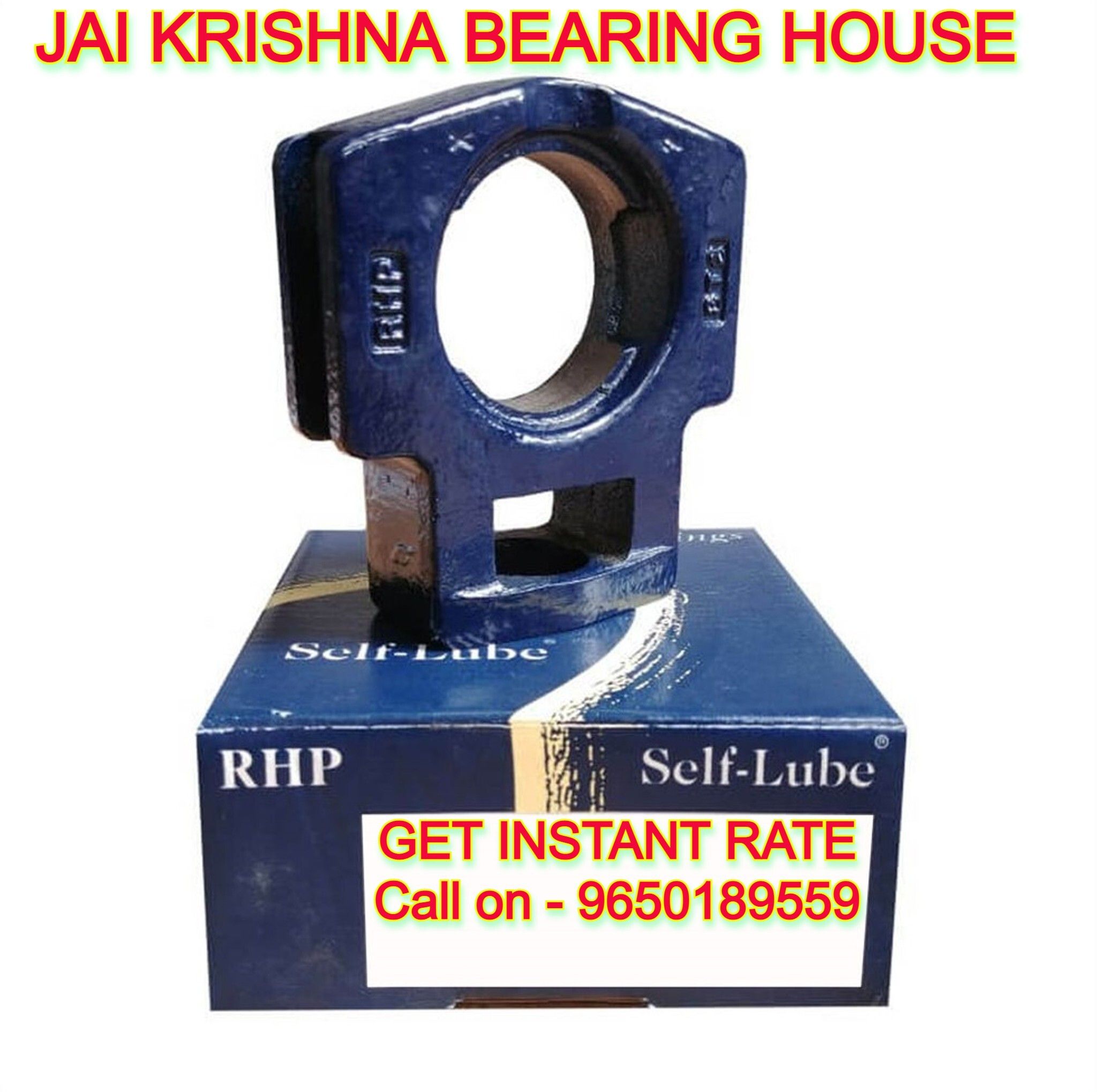

About Axial Load Tapered Roller Bearings RHP

Axial load tapered roller bearings RHP feature a cup and cone assembly. The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage. This bearing construction accommodates combined loads and provides low friction during operation.

Robust Construction for Demanding MachineryRHP double row tapered roller bearings, made from stainless steel, are built to withstand heavy axial and radial loads. Their corrosion-resistant properties and durable design make them a preferred choice for various machinery sectors across India. The silver finish ensures aesthetic appeal and added protection.

Efficient Lubrication for Extended Service LifeThese bearings utilize grease lubrication, which helps maintain optimal operational conditions, minimizes friction, and extends their lifespan. Whether used by manufacturers or distributors, proper lubrication is crucial to retain high performance and reliability in machinery applications.

FAQs of Axial Load Tapered Roller Bearings RHP:

Q: How are Axial Load Tapered Roller Bearings RHP typically installed in machinery?

A: Installation involves careful alignment and seating of the bearings in the designated machinery housing, ensuring both rows are properly positioned to manage axial and radial loads. Professional technicians use precise mounting techniques for optimal performance.

Q: What benefits does stainless steel offer for these double row roller bearings?

A: Stainless steel provides excellent resistance to corrosion, wear, and chemical exposure, ensuring a longer lifespan and reliable service even in challenging industrial environments.

Q: When should grease lubrication be reapplied to these bearings?

A: Grease lubrication should be inspected and reapplied as part of the regular machinery maintenance schedule, or when there are signs of increased noise or resistance in bearing movement.

Q: Where can I source Axial Load Tapered Roller Bearings RHP in India?

A: These bearings are widely available through authorized dealers, distributors, exporters, importers, manufacturers, suppliers, and traders throughout India.

Q: What process does RHP use to ensure the quality of their roller bearings?

A: RHP follows stringent manufacturing and quality control protocols, selecting high-grade stainless steel and employing precision machining to guarantee consistent product performance.

Q: How are these bearings used to improve machinery efficiency?

A: By effectively managing both axial and radial loads, the double row tapered design reduces component stress and enhances overall machinery reliability and operational efficiency.