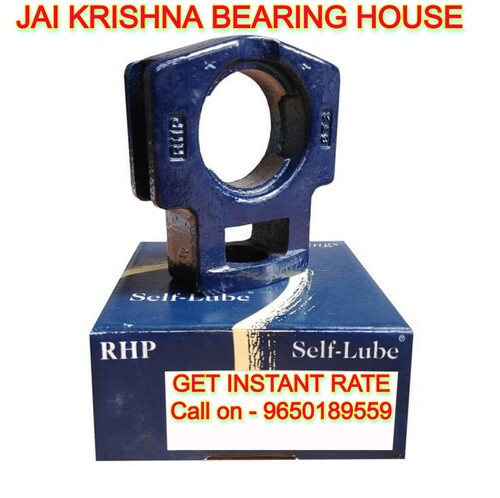

About Needle Roller Bearings Rhp

We are engaged in importing and exporting a qualitative range of RHP Bearings. These precisely constructed products have needle rollers in a retainer installed in a thick-walled outer ring. Our range is extensively used in various industrial applications as these are Compact, durable & easy to handle.

Engineered for ReliabilityOur Needle Roller Bearings Rhp are meticulously designed for heavy-duty machinery. Constructed from robust plastic, these bearings ensure stability and resilience, making them ideal for prolonged industrial use. Quality is at the core of every unit, supporting continuous operations and minimizing downtime.

Seamless Integration and PerformanceWith double row configuration and efficient grease lubrication, these bearings guarantee reduced friction and extended service life. Their silver and black appearance not only looks modern but also signals advanced engineering. Enhance your machinerys efficiency with reliable and easy-to-install bearings.

FAQs of Needle Roller Bearings Rhp:

Q: How should Needle Roller Bearings Rhp be installed in machinery?

A: Ensure the machinery is clean and free of debris before installing the double row Needle Roller Bearings. Align the bearing with the shaft, gently press into place using appropriate tools, and confirm it is properly seated. Follow manufacturer instructions for optimal results.

Q: What makes the plastic material advantageous for these roller bearings?

A: The use of high-quality plastic reduces the overall weight of the bearing, offers excellent corrosion resistance, and ensures smooth operation under load, making them suitable for diverse industrial environments.

Q: When is grease lubrication necessary for these bearings?

A: Regular application of grease lubrication is essential before and during operation to minimize wear, prevent rust, and ensure sustained, efficient performance of the roller bearings in machinery.

Q: Where can these double row Needle Roller Bearings be sourced in India?

A: These bearings are available through authorized dealers, distributors, exporters, importers, manufacturers, suppliers, and traders throughout India, providing easy nationwide access for industrial procurement.

Q: What is the typical process for maintaining Needle Roller Bearings Rhp?

A: Periodically inspect the bearings for signs of wear or contamination, clean them as needed, and reapply grease as per recommended intervals. Proper maintenance extends the lifespan and reliability of the bearings.

Q: How does the double row design benefit machinery performance?

A: A double row configuration enhances load distribution, increases the bearings carrying capacity, and reduces the chances of premature failure, thereby improving machinery stability and operational reliability.