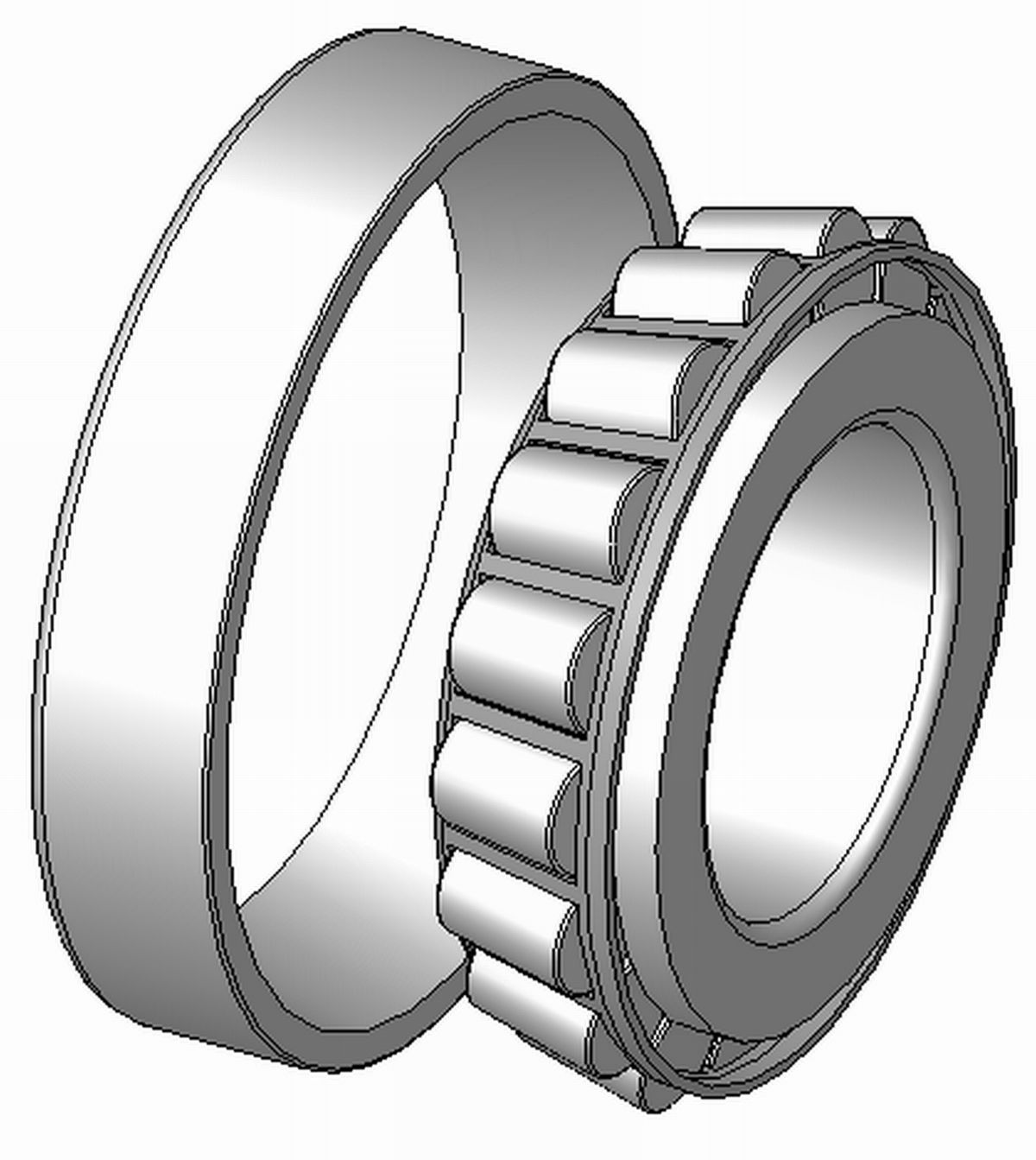

About NEEDLE ROLLER BEARINGS

We cater to the Cement plant, Sugar Plant, Power industries , Pumps Manufacturers, Construction , Dams etc. NRB quality is very superior.NRB usage in heavy earthmoving equipment, light commercial vehicles, road-rollers, cars, engines, heavy commercial vehicles, tractors and trucksExceptional Durability and EfficiencyOur double row needle roller bearings, constructed from premium stainless steel, ensure longevity and dependable performance. The use of oil lubrication reduces wear and heat, contributing to extended bearing life and high operational efficiency in demanding industrial environments.

Versatile Solutions for Industrial ApplicationsDesigned for machinery use, these roller bearings offer versatility across power transmission, conveyor systems, and automated equipment. Their ability to handle high radial loads, coupled with excellent corrosion resistance, makes them suitable for a wide spectrum of industries.

FAQs of NEEDLE ROLLER BEARINGS:

Q: How are stainless steel needle roller bearings maintained for optimal performance?

A: Regular maintenance includes monitoring oil lubrication levels, keeping the bearings clean, and checking for signs of wear. Periodic lubrication ensures smooth operation and extends the lifespan of the bearings in machinery.

Q: What benefits do double row needle roller bearings provide over single row types?

A: Double row needle roller bearings offer higher load-carrying capacity and increased stability, making them suitable for applications with demanding radial load requirements and limited installation space.

Q: When should I choose needle roller bearings with oil lubrication?

A: Choosing oil-lubricated needle roller bearings is ideal when operating in high-speed or high-temperature environments where reducing friction, dissipating heat, and preventing corrosion are essential for machinery longevity.

Q: Where can these stainless steel needle roller bearings be used in industrial settings?

A: These bearings are widely used in machinery such as gearboxes, conveyors, automotive components, and automation systems, where high precision, load capacity, and corrosion resistance are required.

Q: What is the procurement process for purchasing these bearings in India?

A: You can purchase our needle roller bearings directly from our dealership network, as well as authorized distributors, exporters, or importers across India. We also support bulk orders for manufacturers and traders.

Q: How do these bearings benefit machinery operations?

A: The use of high-quality stainless steel and oil lubrication reduces operational downtime, minimizes maintenance costs, and ensures smooth, consistent rotation, thereby improving the overall efficiency of machinery.