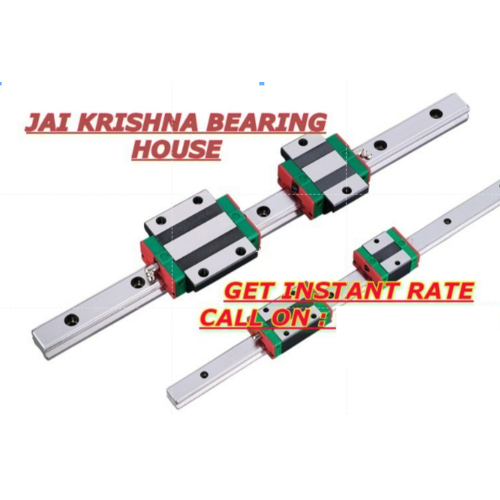

About HIWIN BLOCKS AND RAILS

HIWIN crossed roller bearings are characterised by high rigidity, very high concentricity and high torque capacity in all directions. These features make them ideal for use in industrial automation systems, robots, machine tools, precision rotary tables, measuring machines and medical devices, amongst other things.

Robust Stainless Steel ConstructionHIWIN Blocks and Rails are fabricated using premium stainless steel, ensuring resistance to corrosion and long-term durability even in challenging industrial environments. The silver finish provides an additional layer of protection while maintaining an attractive appearance. This robust construction makes them ideal for a wide range of machinery uses.

Optimized for High-Performance MachineryDesigned specifically for demanding mechanical applications, these rails feature a double row ball bearing configuration. This design offers superior load-bearing capacity and smooth, stable movement under heavy operational loads, making them essential for modern automation and precision equipment.

Reliable Lubrication and Smooth OperationUsing grease as the primary lubrication type, HIWIN Blocks and Rails deliver consistently smooth, quiet, and efficient motion. Regular greasing not only reduces wear and tear but also extends operational lifespan, minimizing maintenance frequency and costs for industrial users.

FAQs of HIWIN BLOCKS AND RAILS:

Q: How do HIWIN double row ball bearing blocks and rails enhance the performance of machinery?

A: The double row ball bearing design of HIWIN blocks and rails provides exceptional stability and higher load-bearing capacity, resulting in smoother, more reliable linear motion. This directly translates to increased precision, efficiency, and durability in machinery operations.

Q: What type of lubrication is required for these HIWIN blocks and rails?

A: These components are designed for grease lubrication, which helps minimize friction and wear. Regular application of grease ensures optimal performance and extends the service life of both the blocks and rails, making maintenance straightforward.

Q: When is it advisable to replace or re-lubricate HIWIN blocks and rails?

A: Its recommended to check and re-lubricate the rails at regular maintenance intervals based on your machinerys usage intensity. Replacement may be necessary if there are signs of excessive wear, unusual noise, or degraded movement despite proper greasing.

Q: Where can I purchase HIWIN blocks and rails in India?

A: HIWIN blocks and rails are available through an extensive network of dealers, distributors, exporters, importers, manufacturers, suppliers, and traders throughout India. You can contact authorized vendors for product selection, support, and after-sales service.

Q: What process ensures the durability of these components?

A: HIWIN utilizes high-strength stainless steel and precision manufacturing techniques to guarantee the longevity and resilience of their blocks and rails. The silver surface finish aids in corrosion resistance, ensuring reliable performance in diverse industrial settings.

Q: How should these rails be used for optimal benefits?

A: For best results, install the rails as per manufacturer guidelines on compatible machinery. Regular cleaning and lubrication with grease are essential to maintain optimal motion and prolong equipment life. These rails are suitable for a wide variety of linear motion applications in industrial automation and machinery.

Q: What are the main benefits of choosing HIWIN stainless steel double row ball bearing blocks and rails?

A: Users benefit from a combination of high load capacity, corrosion resistance, and reliable performance. Their grease lubrication system and durable construction significantly lower maintenance costs and improve the precision and lifespan of your machinery.