About Ball Bearings Grease

We are engaged in offering our clients with a qualitative range of Industrial Bearing Grease. These are designed and fabricated by our vendors in compliance with the international standards and to meet the requirements of rolling bearings as well as their application conditions. Moreover, our range is widely acclaimed by our clients for superb pressure handling attributes and features such as shock loading.

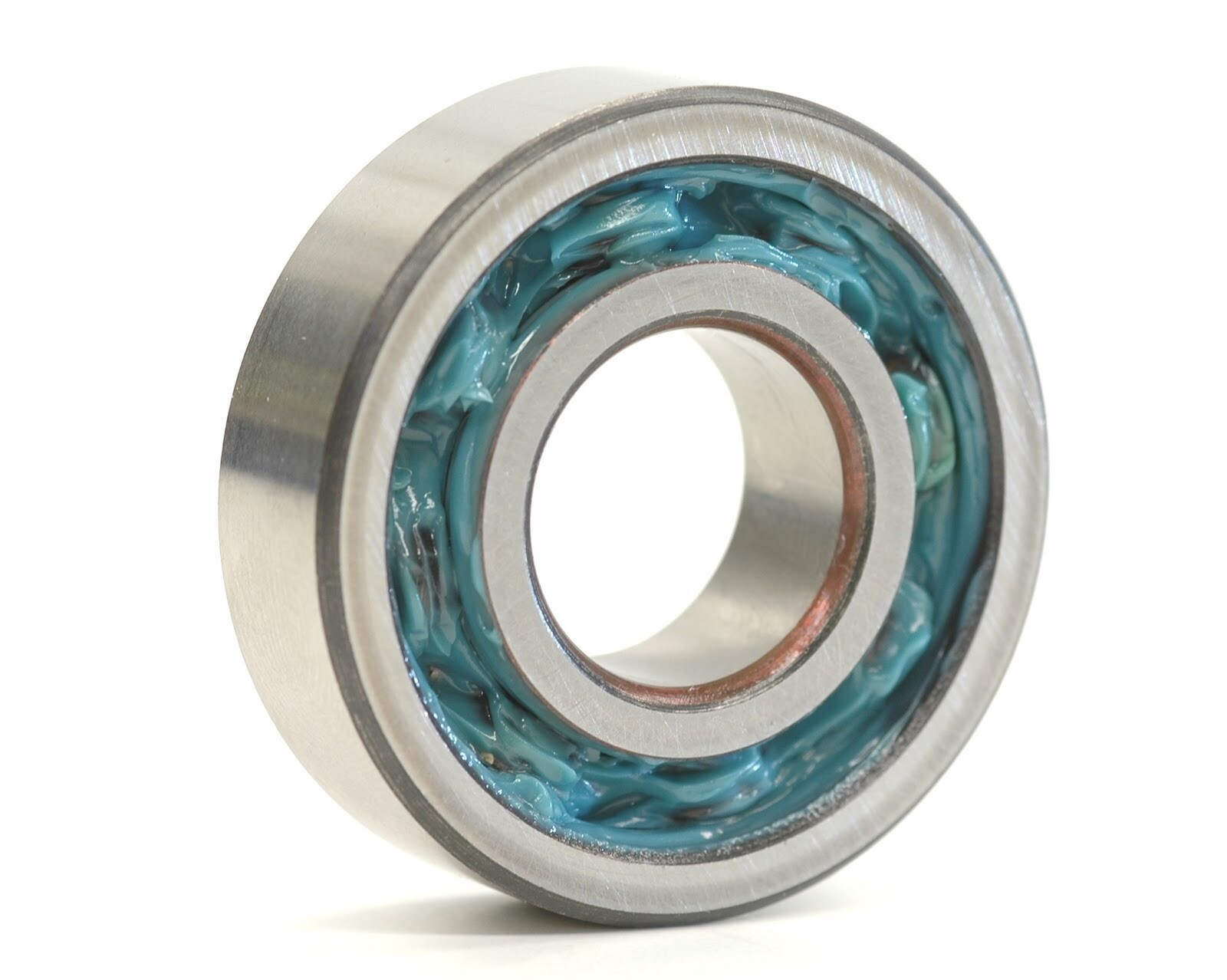

Ball bearing grease is a specialized lubricant designed for use in ball bearings to reduce friction and wear between moving parts. Heres a short specification of typical ball bearing grease.

Versatile Protection for MachineryBall bearings grease offers multi-purpose protection for industrial, automotive, and household machinery. Its robust formula ensures smooth operation in harsh working conditions, preventing breakdowns and extending equipment lifespan. The grease is engineered to withstand high pressure and temperature variations, making it ideal for demanding applications.

Optimize Performance with Reliable LubricationProper lubrication is essential for the efficient operation of ball bearings. By using high-quality ball bearings grease, users can dramatically reduce friction and wear, improve energy efficiency, and guarantee consistent performance. The greases brown color helps with quick identification during maintenance, streamlining operational procedures.

FAQs of Ball Bearings Grease:

Q: How is ball bearings grease applied to machinery?

A: Ball bearings grease can be applied manually using a grease gun or brush, or through automated lubrication systems. The application should be done according to machinery manufacturer guidelines to ensure full coverage and optimal performance.

Q: What advantages does using brown ball bearings grease provide?

A: The brown color of the grease aids in easy identification during maintenance and ensures that coverage is complete. Its advanced formula also provides superior resistance to wear, corrosion, and extreme temperatures, resulting in longer bearing life.

Q: When should ball bearings grease be replaced or reapplied?

A: Grease should be checked and reapplied during regular maintenance intervals, or whenever signs of inadequate lubrication, such as noise or increased friction, are observed. Frequency depends on application intensity and operating environment.

Q: Where can I purchase ball bearings grease in India?

A: Ball bearings grease can be sourced from dealers, distributors, exporters, importers, manufacturers, suppliers, and traders throughout India. It is widely available for all industrial, automotive, and household applications.

Q: What is the recommended process for using ball bearings grease in automotive applications?

A: The recommended process involves cleaning the bearing, applying an adequate amount of grease, ensuring an even coating, and reassembling the parts as per automotive specifications. Follow vehicle maintenance schedules for best results.

Q: How does ball bearings grease benefit household machinery?

A: When used in household machinery, ball bearings grease significantly reduces friction, prevents rust, and ensures smooth and quiet operation. This extends the service life of appliances and reduces the need for frequent repairs.